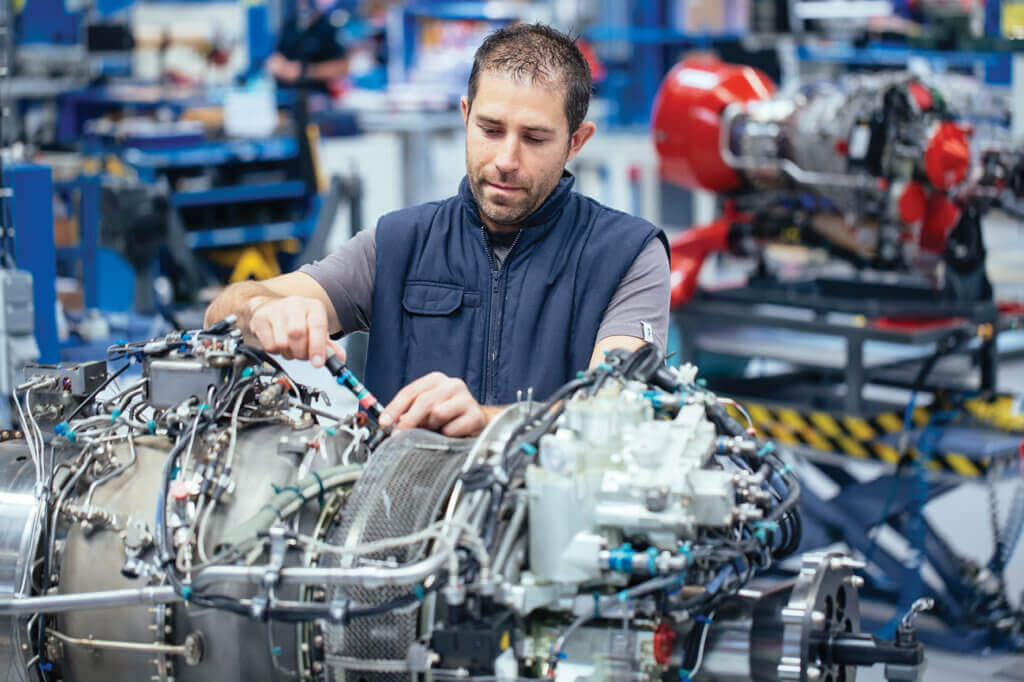

Safran Helicopter Engines has always been committed to innovation and to bringing its customers the most efficient, reliable and cost-effective engine solutions.

Over the years, the French manufacturer has brought to market new products that offer ever more value to helicopter manufacturers and their customers. The improvements include better value and fuel consumption and making aircraft simpler to operate and maintain while upholding the highest possible safety standards.

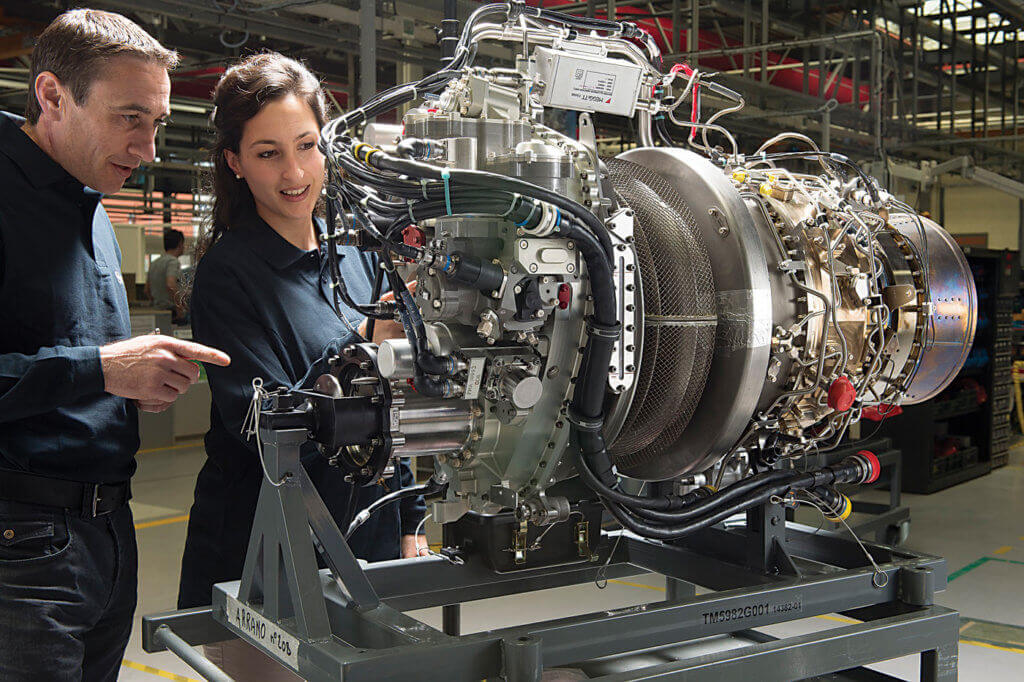

The company’s strategy of partnering with new platforms paid off in 2016 with no fewer than five maiden flights. In January, the Airbus Helicopters H160’s second prototype took off using Safran Arrano engines.

In April, Russian Helicopters’ Ka-62 made its first hover tests powered by the Ardiden 3G engine. In July in China, an AC312E helicopter developed by the Aviation Industry Corporation of China (AVIC), flew for the first time with the Arriel 2H, the latest version of this best-selling engine. It was followed in September by the Indian LUH (Light Utility Helicopter) of Hindustan Aeronautics Limited (HAL) with the Ardiden 1U. The year ended with the maiden flight in Harbin, northern China, of the AVIC AC352 with the WZ16/Ardiden 3C.

“In terms of engine development it has been a tremendous sight to see these new engines taking to the air for the first time, all over the globe,” said Cyrille Poetsch, Safran Helicopter Engines executive vice president, Programs. “I should also mention the Arrius 2R, about to enter service with the Bell 505. All these landmarks are evidence that, today, Safran Helicopter Engines is the preferred manufacturer of the worldwide helicopter industry.”

While the maiden flight is a major step in an engine development program, there is still much work to be done. The Arrano has been run for more than 3,000 hours and recently undertook cold-weather trials with Airbus Helicopters in Canada.

“A major target was to check the engine’s ability to start in temperatures of minus 40C,” said Poetsch.

The 1,100 to 1,300 shaft horsepower (shp) turbine, which will offer 15 percent lower fuel consumption over existing engines in the power range, is on track for 2018 certification, in line with the H160 development schedule.

With 6,000 hours of tests, Ardiden 3 is also embarking on its final development stages.

“The 3G variant will be certified by mid-2017,” said Poetsch. “The WZ16, known in the West as the Ardiden 3C, will be the first helicopter engine to be certified in parallel, in China by CAAC (Civil Aviation Administration of China) and in Europe by EASA (European Aviation Safety Agency).”

EASA certification for the Ardiden 3C is expected by end of 2017, and CAAC certification for the WZ16 in 2018.

This year will also be marked by first deliveries of the Arrius 2R aboard the Bell 505 Jet Ranger X.

“A lot of excitement is surrounding this program and, with extensive maturation tests, we have put a great deal of effort into bringing the engine to market in the smoothest possible way,” said Poetsch. “We have also strengthened our support capacity to benefit small fleet operators.”

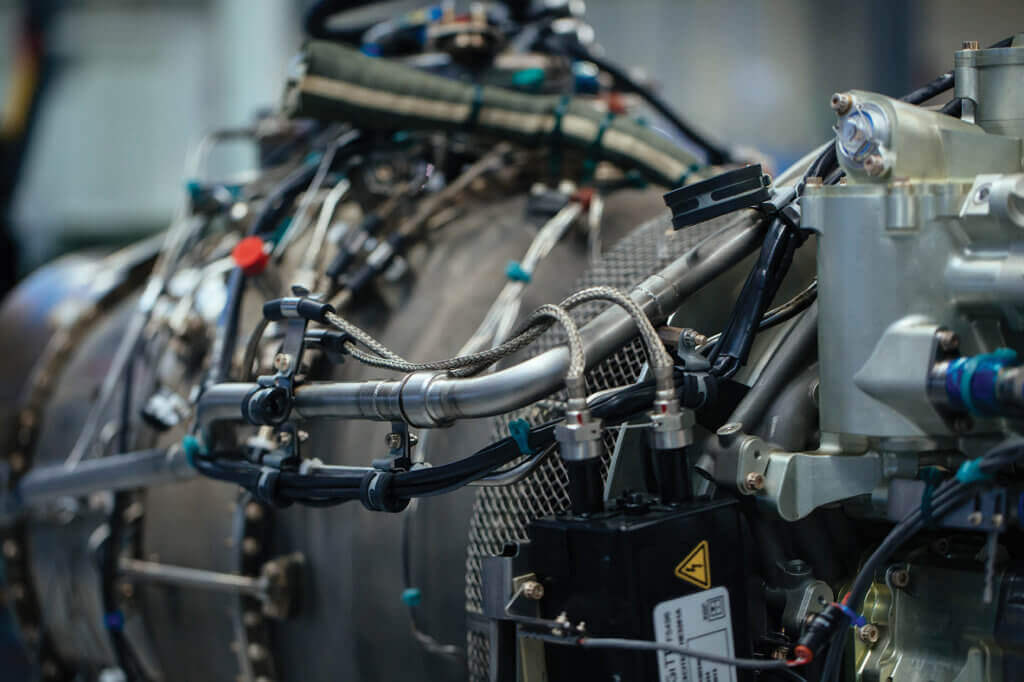

The next step on this journey towards the new generation of helicopter engines will be the new High Power Engines (HPE) family currently in preparation. This new set of 3,000 shp turbines has been specifically designed for the heavy helicopter sector and will incorporate ground-breaking technologies developed over the past five years, as part of the Safran Helicopter Engines research and development (R&D) roadmap. Robust, reliable, powerful and affordable models will cover the 2,200 to 3,000-plus shp power range.

HPE will be the right solution for new 10 ton-plus rotorcraft and will be available at the end of the decade.

Alongside this extensive plan for new products, Safran Helicopter Engines is also investigating new ways of operating a gas turbine. An “eco mode” concept will soon allow a pilot to “pause” an engine while in the cruise, generating fuel savings of around 15 percent. Safran is also working on an auxiliary electric motor to provide additional power during acceleration and autorotation.

Ideas such as these will improve safety margins while at the same time reducing weight and fuel consumption. The first turbines equipped with these technologies could be on the market by 2025.

If you would like to see your company featured in Insight, contact Derek Kast at derek@mhmpub.com.