Machida borescope kits have been essential tools for helicopter maintenance technicians for decades, with cutting-edge technology that lets them look inside an engine the way a surgeon uses an endoscope to see inside the human body.

But what sets Machida apart is the fact engine manufacturers are equally keen about its products, with kit approvals from the biggest names in the industry, including Pratt & Whitney, Rolls-Royce, General Electric, Safran Helicopter Engines (formerly Turbomeca) and Honeywell.

But what sets Machida apart is the fact engine manufacturers are equally keen about its products, with kit approvals from the biggest names in the industry, including Pratt & Whitney, Rolls-Royce, General Electric, Safran Helicopter Engines (formerly Turbomeca) and Honeywell.

“We are the most experienced people in the industry,” said Jitu Patel, vice president of Machida’s industrial division. “We’ve been doing it for 40 years, and we’ve been at HAI Heli-Expo for more than 28 years. Not all companies can say that.”

Machida’s industrial division traces its history back to 1978, when Pratt & Whitney and the U.S. Air Force approached Machida to design a borescope for the F-100 aircraft engine.

The result was one of the first flexible industrial endoscopes (if not the first). Word quickly spread about its effectiveness as a non-destructive testing tool, and the market expanded dramatically.

Today, Machida is the leading borescope manufacturer for helicopter and fixed-wing engines. It has also developed borescopes for the automotive, nuclear, petrochemical, power generation and refining industries, among many others.

Today, Machida is the leading borescope manufacturer for helicopter and fixed-wing engines. It has also developed borescopes for the automotive, nuclear, petrochemical, power generation and refining industries, among many others.

“We manufacture everything here in the United States,” said Jennifer Kempsey, marketing and operations manager for Machida. “Our facility is where everything is put together, so we have the ability to expedite things and take care of our customers in a timely manner.”

Manufacturers trust Machida so thoroughly that they often consult with the company when developing new engines.

“They contact us when they’re still in the development stages, and then Jitu, myself and our R&D team work together to come up with a design concept so that they can reach their inspection goals,” said Kempsey.

“Since we have the ability to design custom [products], we come up with what will become the standardized inspection requirement for that engine.”

Machida will be showcasing its borescopes and videoscopes at Heli-Expo this year with a live engine display at the Machida booth (No. C1250).

Machida will be showcasing its borescopes and videoscopes at Heli-Expo this year with a live engine display at the Machida booth (No. C1250).

Show-goers will be able to test-drive Machida products on authentic Pratt & Whitney, Safran and Rolls-Royce engines to get a sense of how they perform in real-world situations.

“The other good thing is that our people will be there,” said Patel. “They are all experienced, 40 years of experience with the engine and the borescope, so questions can be answered at the booth.

“We’re not only offering a borescope; we’re offering great service.”

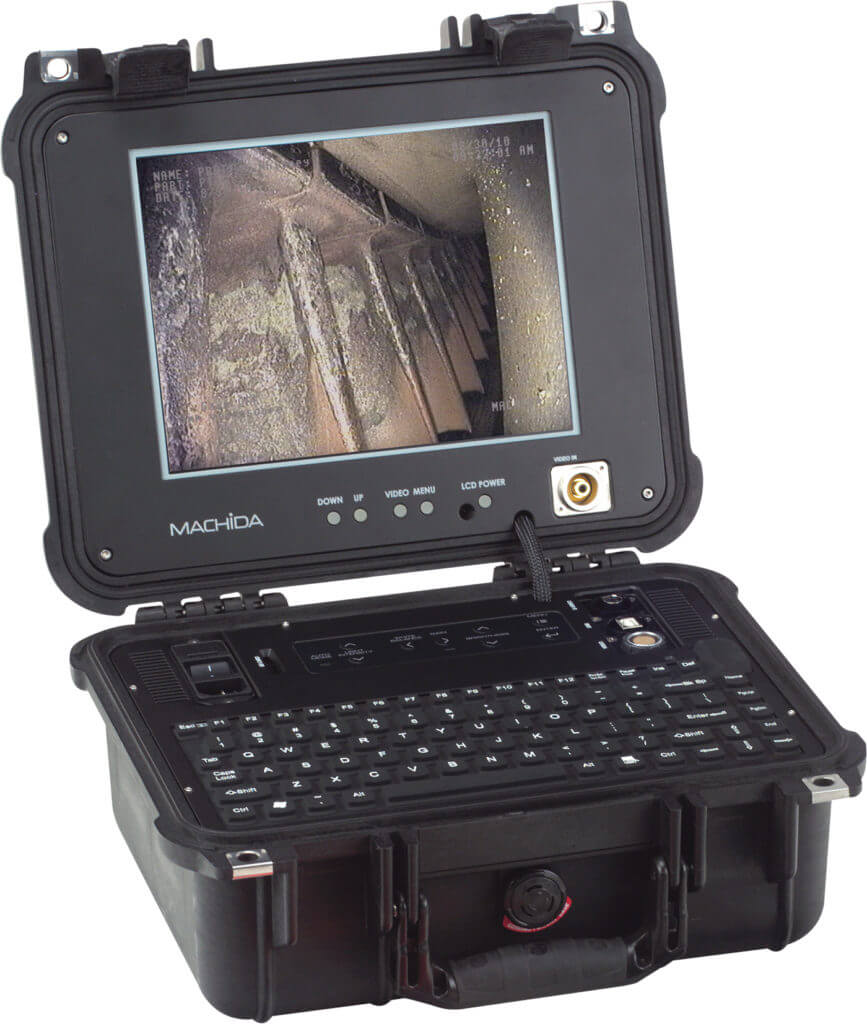

Visitors to the booth will be able to test-drive the Machida PWC34910-109 kit for Pratt & Whitney engines, which contains a three-millimeter videoscope, a 10.4-inch (26-centimeter) video processor, a built-in keyboard, SD card and carrying case. The entire kit weighs about 16 pounds (seven kilograms).

The three-millimeter scope has a tight bending radius that allows Machida to use it for many types of Pratt & Whitney engines. It also has the highest resolution available in the industry, said Patel, with the ability to record both video and still images.

The three-millimeter scope has a tight bending radius that allows Machida to use it for many types of Pratt & Whitney engines. It also has the highest resolution available in the industry, said Patel, with the ability to record both video and still images.

“Plug-and-play,” added Kempsey. “It’s very simple to use.”

Heli-Expo 2018 attendees can also try out the Machida VSC-4-140-NLT kit for Safran and Pratt & Whitney engines. This kit includes a four-millimeter videoscope with a 10.4-inch digital processor and detachable side view adapter. It offers a wide field of view, new zoom features, easy-to-use software, gain control, high-definition, picture-in-picture viewing, portable image archiving, image enhancement from low- to super-high resolution, and video recording capabilities.

“They’ll be able to use the engine to stage and inspect it like they would at the hangar,” said Kempsey.

Machida is based in the U.S. but has many international clients in both the helicopter and fixed-wing industries.

Its extensive custom product catalog also includes approved engine manufacture kits for on-wing blending (also known as bore blending) for General Electric, Pratt & Whitney and Rolls-Royce engines. Bore blending allows maintenance professionals to go into borescope ports and repair damaged blades by filing out impact damage from foreign object debris strikes.

Its extensive custom product catalog also includes approved engine manufacture kits for on-wing blending (also known as bore blending) for General Electric, Pratt & Whitney and Rolls-Royce engines. Bore blending allows maintenance professionals to go into borescope ports and repair damaged blades by filing out impact damage from foreign object debris strikes.

Machida employees are more than happy to answer questions at Heli-Expo, and all visitors are enthusiastically welcomed to stop by the Machida booth. They can also submit questions by email to info@machidascope.com or visit the Machida website, which has comprehensive descriptions of all Machida products.

“We get back to our customers almost immediately,” said Kempsey. “We’re really good with our response time.”

Machida has built a sterling reputation for both product quality and service quality over 40 years in the borescope business, rooted in the fact it was also an industry pioneer.

Innovation helped create Machida’s industrial division, and a commitment to exceptional quality has sustained it ever since–along with a genuine desire to help customers in every possible way.

“All of our customers are like family to us,” said Kempsey. “We take really good care of our customers.”