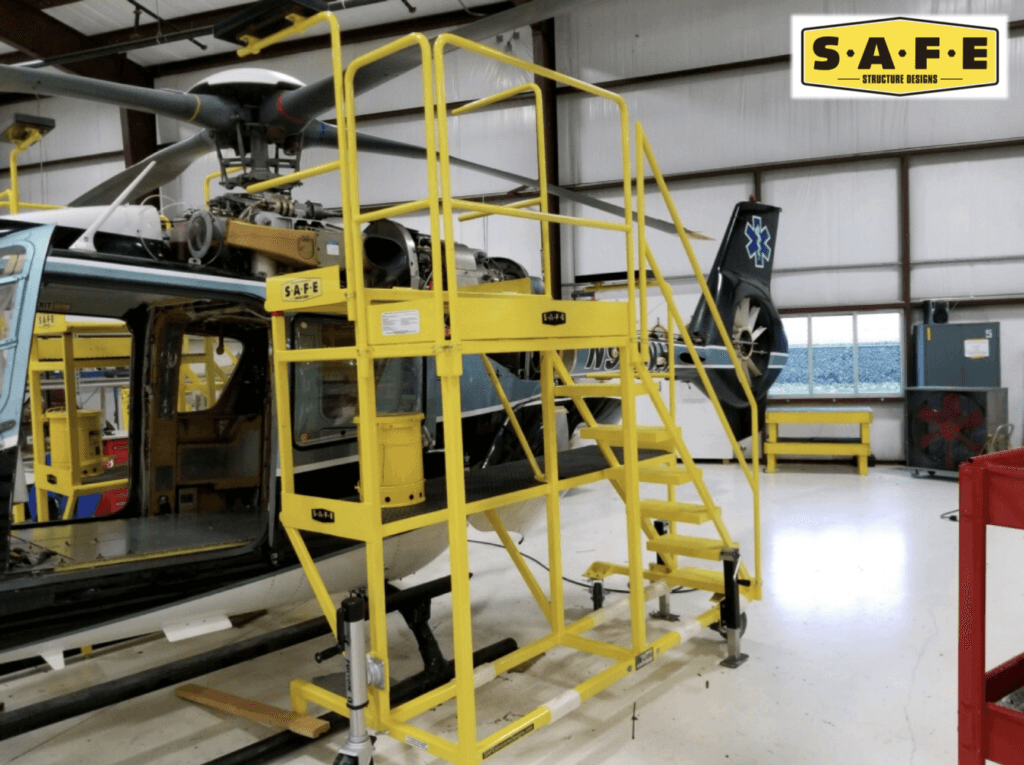

S.A.F.E. Structure Designs — a global leader that designs, engineers, and manufactures custom ergonomic aircraft and marine maintenance stands, fall protection platforms, and hangar equipment — has announced that it has successfully delivered its RW-SS1-B206-S and RW-SS2-B206-S engine, transmission, and main rotor head maintenance stands to United Rotorcraft, an Air Methods division, in Decatur, Texas, for its fleet of Bell 206s.

S.A.F.E. Structure worked with United Rotorcraft to enhance and improve its safety and efficiency when working on the aircraft. S.A.F.E.’s RW-SS1-B206-S and RW-SS2-B206-S maintenance stands were designed to support the Bell 206, Bell 407, Bell 429, and OH-58, and have been sought after and tested by aircraft mechanics worldwide.

United Rotorcraft is the first of S.A.F.E.’s customers to receive maintenance stands with S.A.F.E.’s new innovative enhancements to increase the ergonomics and efficiency of the technician.

These additions include diamond plate anti-fatigue decking manufactured with non-skid high-tech oil and chemical resistant rubber for soft cushioning to provide essential comfort to the mechanic’s feet, legs and back; FOD oily waste can which includes a self-closing, foot-operated lid to dispose of oily rags to prevent a fire hazard; and a FOD handrail hanging bag to dispose of small particles that may be dropped on the stand or hangar floor.

All future S.A.F.E. Structure maintenance stands will include each of these enhancements. S.A.F.E. is confident that these additions will set it above its competitors.

“The primary goal in adding these new ergonomic enhancements is to preserve the health of the mechanics that utilize our stands. S.A.F.E. now provides an innovative system to improve the physical work condition of the technician. This system has proven to prevent developing injuries on the job that may hinder their life outside of work,” said Johnny Buscema, president and CEO of S.A.F.E. Structure Designs.