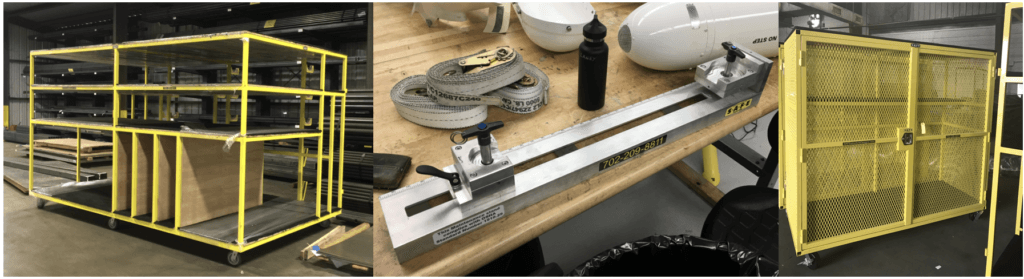

S.A.F.E. Structure Designs, a leader in ergonomic safety-first aviation maintenance equipment for the civilian and military sectors, has announced the delivery of its custom MH-60 pitch adjustment tool, MH-60 cowling rack, and MH-60 parts cage for the United States Coast Guard’s (USCG) fleet of Sikorsky MH-60 aircraft in Sitka, Alaska.

S.A.F.E.’s industry-wide success stems from its ability to work closely with customers such as the USCG. The company’s collaborative design process yields highly-customized products that enhance and improve aircraft maintenance and safety. The S.A.F.E. products delivered to the USCG in Sitka were designed to support the MH-60; these products have been sought after and tested by aircraft mechanics worldwide.

The technicians utilizing the newly delivered custom hangar equipment report that it has helped to significantly increase the efficiency of their maintenance team. Additionally, S.A.F.E. has also begun the design process for a custom tail rotor stand that is unlike any other on the market for Sitka’s MH-60s.

“I am always impressed with aircraft maintenance facilities that promote safety and efficiency as their number one priority. The United States Coast Guard in Sitka, Alaska, runs a highly efficient and safe operation,” said Johnny Buscema, S.A.F.E. Structure’s president and CEO, when asked about the delivery. “We at S.A.F.E. are honored to be their chosen source for ‘safety first’ maintenance stands, hangar equipment and specialty tooling.”

S.A.F.E. is an innovator in the design and manufacturing of aviation maintenance stands, fall protection platforms, production line platforms, hangar equipment, portable field equipment, various types of steel structures, and specialty tooling for all components. This equipment increases safety while enhancing the efficiency of maintenance crews as they work on their equipment and aircraft.