Pratt & Whitney Canada (P&WC) has been in the business of designing, manufacturing and servicing helicopter engines since the early 1970s.

Over the years, the company has delivered more than 16,000 helicopter engines and the entire fleet has flown in excess of 61 million hours.

“It’s an understatement to suggest that we have depth in the global aviation industry because over the years we’ve truly become an integral part of it,” said Nicolas Chabée, vice president of marketing at P&WC, responsible for helicopter engines. “We are in the business for the long haul and it’s with that same perspective we bring all of our products and services to market.”

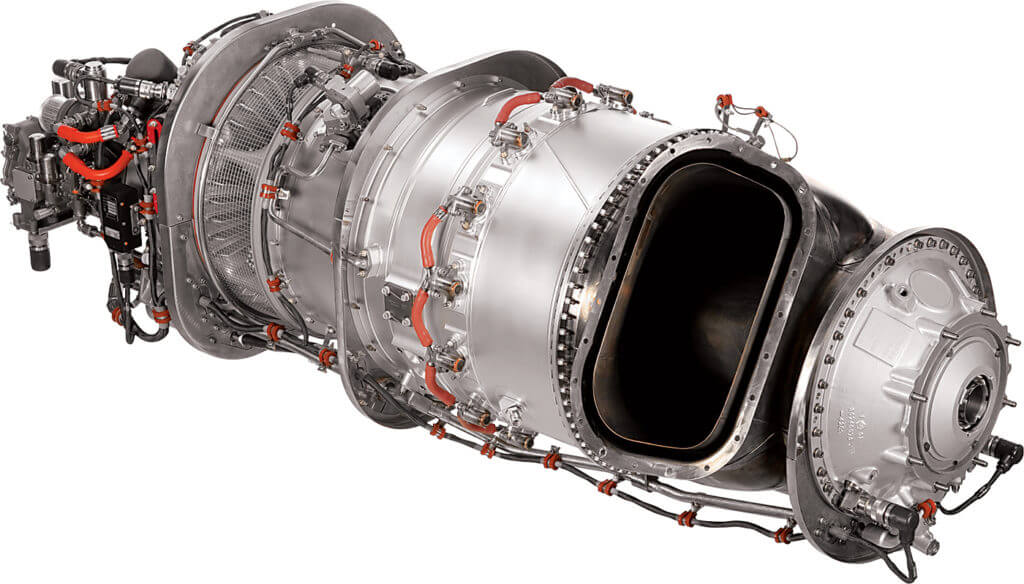

The company is best known for its iconic PT6A turboprop engine, which changed the face of general aviation around the world. P&WC took its PT6A experience and parlayed it into three distinct helicopter engine families which all share the same PT6 architecture.

The company is best known for its iconic PT6A turboprop engine, which changed the face of general aviation around the world. P&WC took its PT6A experience and parlayed it into three distinct helicopter engine families which all share the same PT6 architecture.

“We were able to extend the PT6A’s reputation for exceptional reliability to our turboshaft engine programs and we consequently built a major presence for ourselves in the helicopter industry,” said Chabée. “We first won over helicopter OEMs by demonstrating how we could collaborate on ensuring the powerplant was fully and seamlessly integrated with the helicopter itself. Then, we won over operators by producing engines with rock-solid reliability along with the exceptional value that such reliability and availability mean.”

He said an excellent case in point is the PT6C-67C engine, which powers the twin-engine AW139 helicopter from Leonardo. The PT6C-67C is a derivative of the PT6A-67 large turboprop engine series, which has accumulated more than 27 million flight hours and has been certified for single-engine instrument flight rules (SEIFR) for the Pilatus PC-12.

“We have delivered more than 2,000 PT6C-67C engines to more than 260 operators in 78 countries,” said Chabée. “The fleet has flown more than four million hours and the fleet leader is currently at 10,000 flight hours.”

Setting performance standards

He said the PT6C-67C engine bears a number of performance metrics that have consistently set it apart from similar engines on the market.

- It has an indisputable availability track record at 99.1 percent compared to the industry benchmark at 98 percent;

- The engine’s total in-flight shut down (IFSD) rates are six times better than the industry benchmark and basic IFSD rates are seven times better than the industry benchmark at one basic IFSD per 643,000 flight hours; and

- Basic unscheduled removal (BUR) rates are four times better than the industry benchmark at one BUR per 32,000 flight hours.

“You simply won’t find this kind of performance and reliability on an engine in this class,” said Chabée. “To have an engine that outperforms its competition on so many levels is a tremendous competitive advantage for operators of AW139 helicopters, a fact which we believe to be a key contributing factor to the program’s success. Of course, reliability means more time on wing and that means cost savings and high dispatch availability.” Chabée said it’s not just the engine’s reliability and availability that represents value for operators, it’s the economics of the engine as well.

“You simply won’t find this kind of performance and reliability on an engine in this class,” said Chabée. “To have an engine that outperforms its competition on so many levels is a tremendous competitive advantage for operators of AW139 helicopters, a fact which we believe to be a key contributing factor to the program’s success. Of course, reliability means more time on wing and that means cost savings and high dispatch availability.” Chabée said it’s not just the engine’s reliability and availability that represents value for operators, it’s the economics of the engine as well.

- Based on third-party data (Conklin & de Decker Associates Inc.), the PT6C-67C engine’s direct maintenance costs are exceptionally competitive in its power class;

- The engine generally exhibits performance-margin retention;

- The PT6C-67C engine has accommodated incremental increases in maximum take-off weight (MTOW) that Leonardo has undertaken on the AW139 platform since entering into service; and

- Its already generous 5,000-hour time between overhaul (TBO) interval can be further escalated based on satisfactory engine sampling; today’s fleet leader is currently at 6,000 hours.

An engine with global support

PT6C-67C customers can rely on the some 2,000 employees in P&WC’s global customer service organization that never sleeps. It includes two Customer First (CFirst) centers in Longueuil, Quebec, and Singapore; more than 100 field support representatives; another 100 Mobile Repair Team (MRT) technicians; seven parts distribution centers; and 13 training centers in strategic locales around the globe.

P&WC’s FAST (full-flight data acquisition, storage and transmission) engine health management solution that helps optimize operations, reduce costs and increase helicopter availability, has been certified for the PT6C-67C engine.

“Our customer support activities are driven by a collaborative model wherein we believe that we succeed only when our customers succeed,” said Chabée. “Our customer relationships are intentionally strategic, not merely transactional. For example, we recently introduced platinum-level ESP (pay per hour) maintenance coverage for our PW200 helicopter engine portfolio and we are considering doing the same for other engine programs, including our PT6C-67C.”

More than 30 PT6C-67C rental engines are inventoried at facilities in Frankfurt, Montreal, Singapore and Australia.

More than 30 PT6C-67C rental engines are inventoried at facilities in Frankfurt, Montreal, Singapore and Australia.

Airframe integration

“P&WC has a long-standing relationship with Leonardo Helicopters and we power a number of their platforms,” said Chabée. “One of the reasons that the PT6C-67C has performed so well on the AW139 is because of the way in which we worked with Leonardo throughout the design, and certification phases, and finally EIS. It’s important to keep in mind that the engine and the helicopter airframe were developed essentially in tandem. We do this to ensure that the engine and helicopter are seamlessly integrated and together work as a single system.”

He added that once the helicopter enters into service, the relationship between the two companies continues as teams work to track and analyze the ongoing performance of the engine fleet. This entails weekly–if not daily–dialogue with Leonardo augmented by several face-to-face meetings every year. The relationship is a well-oiled machine that’s responsive and predisposed to rapid issue resolution.

“Since the entry into service of the AW139 14 years ago, we have worked with Leonardo on what’s essentially a master class on the performance characteristics of the PT6C-67C engine,” said Chabée.

“The result is a deep understanding of how the engine operates under different conditions and while performing various missions. Like P&WC itself, the engine plays a long game and yet remains evergreen. That’s something that gives our customers the best of both worlds; a competitive advantage that no one else can match.”