In the small town of Aurora, Oregon, change is in the air. For more than 60 years, it has been home to one of the helicopter industry’s most enduring heavyweights — the heavy-lift specialist Columbia Helicopters. Founded in 1957 by industry pioneer Wes Lematta, Columbia has seen global success with its instantly-recognizable fleet of tandem-rotor aircraft. Throughout that time, ownership of the company remained in the hands of the Lematta family. But on July 18, 2019, the company announced the start of a new phase in its storied history, with AE Industrial Partners agreeing terms with Columbia to acquire the company.

While the change in ownership may be the most dramatic shift at the company, it’s just one of a range of recent evolutions taking place at Columbia, as it strengthens its market position and adapts to take advantage of new opportunities in the increasingly-packed heavy-lift sector.

Today, Columbia has a staff of over 800, and a giant tandem-rotor fleet that includes 11 Model 234 UT/LR Chinooks (capable of lifting 28,000 pounds/12,700 kilograms on the hook), 14 Model 107-II Vertols (11,500 lb./5,220 kg on the hook), and three Boeing CH-47D Chinooks (26,000 lb./11,800 kg on the hook). Its operations take it across the United States, Canada, Papua New Guinea, and Afghanistan.

For the last two years, the company has been led by Steve Bandy, who joined Columbia in 1989 as a co-pilot. He has worked in a series of increasingly senior leadership roles at the company over the years, ultimately being promoted to president in June 2017.

“I was always given the opportunity to grow my capabilities and advance within the organization, which is a really great thing with this company — the trust it puts in its people,” said Bandy. “My story is not uncommon. Columbia truly provides tremendous opportunity for people who are interested in achieving excellence and mastering whatever challenge is put in front of them.”

In return, Columbia enjoys long tenure and loyalty from its employees, with Bandy highlighting that several people have been at the company for more than 40 years.

“Our tagline is: “dedicated people, inspired solutions,” said Bandy. “We don’t underestimate how dedicated our employees are, and the inspiring things they do every day are pretty impressive.”

While Columbia has always done some firefighting, logging work provided the bulk of its revenue as recently as the early 2000s. But today, the company does very little logging, and with 12 aircraft supporting military operations in Afghanistan, government and military support contracts have become a crucial part of its business.

This government charter work is one of the core segments for the company’s aviation services division, along with onshore oil-and-gas support, construction, forestry and stream restoration, and firefighting. Despite a general industry downturn in the oil-and-gas market, Columbia has maintained a strong presence in Southeast Asia (primarily Papua New Guinea) working in the sector.

And in its firefighting operations, the longer and more severe fire seasons of the last few years have provided some stable work with the U.S. Forest Service, and Columbia is also exploring new opportunities to fight fires outside the U.S.

Of course, Columbia isn’t just an operator — it also functions as a maintenance, repair and overhaul (MRO) provider and, following its acquisition of the 107 and 234 type certificates from Boeing in 2006, an original equipment manufacturer (OEM).

According to Santiago Crespo, vice president of business development and marketing, it’s this vertical integration that allows the company to maintain an extraordinarily high fleet availability percentage that’s in the “mid 90s.” He said this was one of the things that set Columbia apart from its competition — alongside its use of the 234.

“We differentiate ourselves because we have the standard transport category 234, and we’re still the only company that operates the standard transport category Chinook,” said Santiago Crespo. “That has some significant benefits, especially when you’re operating in international markets or operating for certain customers. The 47D is a great platform, but still it’s a restricted category aircraft — you can’t transport passengers.”

Under new ownership

The recent announcement of the change in ownership at Columbia followed a high profile acquisition attempt from fellow industry juggernaut Bristow Helicopters. Announcing the $560 million move in November 2018, then-Bristow CEO Jonathan Baliff labelled it “the largest transaction in [Bristow’s] history.”

However, Bristow was facing considerable financial and operational headwinds at the time, and was unable to close the deal by the scheduled completion date of Dec. 31. By February, the two companies announced they had terminated the process — at a cost to Bristow of $20 million.

“It was a very public process, so obviously people knew we were in play at that point and we had a lot of people reach out [about purchasing Columbia],” said Bandy. Columbia’s management team narrowed down the list of potential suitors, and ultimately agreed a sale to AE Industrial Partners — a private equity firm specializing in aerospace, defense and government services, power generation, and specialty industrial markets.

“They have a keen understanding of the industry, with lots of resources and knowledge that will benefit the company,” said Bandy. “What it does, is it takes us from an organization that’s been very comfortable in its size and space and moves us into a more dynamic position. I think we have been positioned to be able to grow and we are a great platform to grow in the industry — we have just been waiting for that opportunity. And I think that is what AEI unlocks for us.”

That expansion may be in fleet size, as well as market scope. “We have essentially had the same sized fleet — other than the addition of the 47Ds a few years ago — for several decades,” said Bandy.

Any fleet expansion would likely be through the addition of further tandem-rotor aircraft, he added. “As the type certificate holder and the production certificate holder of the 107 and the 234, we have complete control over our supply and our configuration of aircraft components,” said Bandy. “So, I think that would be our primary focus.”

In 2012, Columbia bought a fleet of 10 Vertol 107s (retired HKP-4s) from the Swedish military and have started the process of making them operational. The three former U.S. military CH-47Ds already flying in the Columbia fleet are from a batch of 11 it purchased between 2014 and 2015. More recently, its 234 ranks swelled with the arrival of three of the type from Taiwan in 2016 (these were the last three 234s available on the market, so the purchase made Columbia the only operator of the type in the world).

The market for heavy-lift work is buoyant, said Bandy. “There is more demand than we have resources,” he added. “Our DoD [Department of Defense] operations have absorbed every resource we have been able to offer. We see strong demand in the emergency response type of markets and again our biggest challenge has been providing enough resources to meet the demand.”

And this is despite the recent flood of aircraft capable of medium- to heavy-lift operations into the utility market, through the civilian debut of former U.S. military Sikorsky UH-60 Black Hawks and sale of further military CH-47Ds, and the repurposing of much of the offshore Airbus H225 Super Puma fleet into utility operations.

In terms of the former, Bandy said Columbia has a significant advantage with its fleet being composed of transport category — rather than restricted category — aircraft.

And while Bandy said Columbia “would have explored options” with the Super Puma if the Bristow acquisition had completed, it’s not a type of aircraft the company is currently looking to acquire.

“We operate at such a high tempo that the support structure behind the aircraft is really critical for us,” he said. “First generation OEMs sometimes lose interest in legacy products that they are no longer able to sell as a new product, and so we will just have to see how that [Super Puma] support structure holds up.”

An MRO specialist

Kurt Koehnke, vice president of maintenance, is the longest-tenured vice president at the company, having been at Columbia for 32 years. He said MRO growth has been one of major areas of change at the company over the years. All told, the MRO team now totals 275 technicians.

Typically, Columbia’s aircraft deploy in the U.S. with a service van and an equipment trailer that stocks a large number of parts. Larger items such as transmissions and engines will either be driven out or flown by Columbia’s own Beechcraft King Air, which is equipped with a cargo door.

The general change in operation type over the years has impacted the MRO department as well as the flight crews.

“This transition to what we call charter — which is this government work in Afghanistan — that’s a big change,” said Koehnke. “That’s 200 hours a month consistently on the airframes there, so it’s a big transition in the maintenance. We’ve got nice facilities in Bagram, in Jalalabad. We’ve transitioned technical experts from avionics and sheet metal and embedded them in the field crews over there.”

Columbia has been in Afghanistan for eight years, during which time it has brought new capabilities to its government customer, such as delivering supplies to remote operating bases with a 200-foot long line to avoid damaging them with the aircraft’s downwash when using a shorter line. The company originally went with four 107s, and has grown that presence to nine 107s and three 234s.

A team of 84 people takes care of the MRO requirements of the 12 aircraft in Afghanistan. Each of the 107s requires a team of six mechanics (three on-shift), with the three 234s each staffed by 10 mechanics (five on-shift). They work a shift pattern of 28 days on, then 28 days off.

As the aircraft only fly day visual flight rules, maintenance is performed overnight, and the size of the team allows Columbia to keep up with scheduled maintenance and perform unscheduled work as required – ensuring the availability rate stays extremely high.

The capabilities of the team are extensive, and they are supported by an enormous inventory that includes thousands of line items, from major dynamic parts down to circuit breakers and nuts and bolts. This allows them to perform almost every type of maintenance, from complete skin repairs to major structural repairs.

“If we do a mod or a service bulletin, obviously we do it right there in-country — it’s too expensive to send the aircraft home,” said Koehnke.

With the CH-47D, Koehnke said the transition to supporting that aircraft has been relatively straightforward due to the similarities to the 234, and the fact that many employees are former military personnel who have worked on the type before.

“We’d already been working on Ds for external customers before they came through, so we really had a jump on tooling and technical experience and so on,” he said.

When the aircraft arrived, they were completely stripped and the components were individually checked, repaired/overhauled as necessary, and then put in Columbia’s inventory. Parts are then taken from the inventory as the aircraft are rebuilt. With 11 aircraft, the company has a significant supply of spares to keep the flying aircraft serviceable.

In terms of the challenges facing the MRO department, Koehnke said the logistics of maintaining aircraft in remote locations such as Afghanistan and Papua New Guinea — clearing the hurdles of licensing, visas and security clearances — can be significant.

Additionally, he said the company was having to adapt to the ongoing shortage of mechanics in the industry.

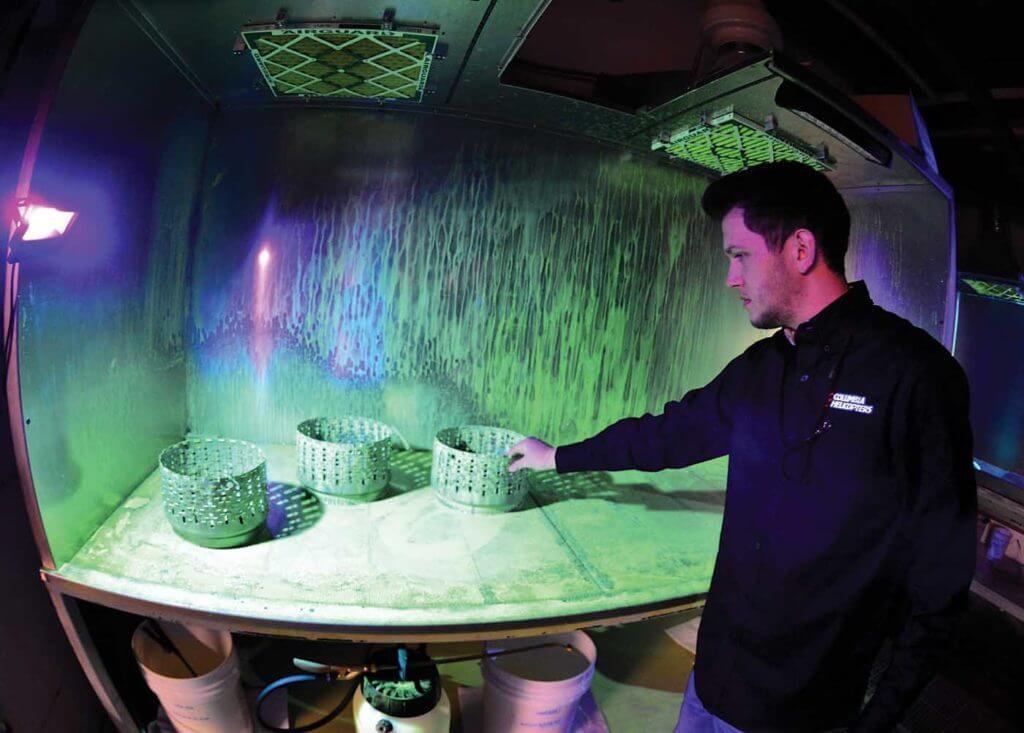

“We’ve started a program where we’re actually hiring young individuals as a helper,” said Koehnke. “They can’t inspect, they can’t turn wrenches, but we embed them in the shop and they do parts cleaning, running tools, and everything else to support the mechanics. And then we move them to a mechanic trainee, and we have several steps in there until we can get them a license — and that’s really helped.”

Columbia has even invested the time to go to high schools to plant the seed of a career, and invited classes to tour its facilities.

Engineering an evolution

The driver behind much of the ongoing evolution at Columbia is its in-house engineering department. Rob Roedts, director of engineering and production, leads this team of over 60 people, who allow the company to quickly design, develop, and implement any necessary changes to the fleet.

The 234 has been a major beneficiary in this, with Columbia having made over 1,000 changes to the aircraft’s original design, from the main rotor blades down to the landing gear.

“We’ve had to make design changes to make that aircraft work reliably in our environment,” said Roedts.

One of the more dramatic was completely gutting and rebuilding the 234’s cabin in preparation for part 135 work in Afghanistan, from installing new seats to changing the material in certain types of washers — and everything in between.

The acquisition of the 11 CH-47Ds and conversion for civilian operations has presented a new type of challenge.

“The Army had set up those aircraft to have a huge amount of maintenance, and that phase maintenance program is good for the military because they have hundreds of aircraft, and if they need to down half of them, they can, and still sustain their operation,” said Roedts. “We can’t do that. So the challenge is, how do you take that aircraft and get it to a level of operating in the 90-percentile availability rate?”

The answer involved solving several other issues, such as figuring out how to build or acquire parts for a restricted category aircraft, and where to find the crews who could work on them.

“A lot of stuff we have done for the 234 couldn’t directly transfer over to the 47Ds, for myriad reasons, and so there was a lot of reverse engineering that we had to do,” said Roedts. “We had to get it all online to get those aircraft to operate the way we need them to.”

The biggest project for the D models was the creation of a 2,800-US gallon internal firefighting tank, with Columbia working with Simplex Aerospace (which owns the STC for the tank) to bring it to the market.

The tank, which Simplex claims is the largest helicopter firefighting system in the world, is comprised of a roll-on/roll-off internal tank system connected to an external plenum through the CH-47D’s hook well. It includes a 12-foot-long, 10-inch-diameter hover pump that was designed to refill the tank in less than one minute. The entire load can be dropped in less than four seconds, but the pilot has the capability to select different drop patterns to allow for multiple drops, if needed. The never exceed speed for the tank is 140 knots, while water drops can be made at up to 100 knots.

Two of Columbia’s CH-47Ds have the tank installed and are on exclusive use contracts; the third aircraft is on a bucketing contract and uses a 2,600-US gallon SEI Bambi Bucket.

Columbia’s engineering team also developed a carbon-fiber bubble door for the aircraft; worked on the subsystems required to allow the CH-47Ds to fly the various operations required by the company (including a utility power control system that allows the pilot to control whatever is on the long line); and installed all-new avionics.

Roedts said the benefit of being both OEM and operator for Columbia’s engineers is the short feedback loop. When a design change enters operation, the team is sometimes getting feedback at the aircraft’s first stop on the first day.

“It can be challenging at times, but at the end of the day it’s huge for us, because we are completely able to respond to the needs of the field, get the design changes incorporated, and continuously evolve the product,” he said.

Future evolutions to the Columbia fleet could touch on increasing pilot’s situational awareness or automation, and finding ways to reduce the time it takes to reconfigure the aircraft between jobs, said Roedts.

“The more configurable the aircraft, and the faster you can do it, the more capable a product it is to your customers,” he added.

Future growth

What does the future hold for the company more broadly? Bandy said Columbia will look to take more advantage of its extensive MRO/manufacturing capabilities — illustrated by the announcement last year that Columbia would be taking on production and support for GE Aviation’s T58 and CT58 engines (powering aircraft including the Boeing CH-46 and 107-II, and Sikorsky SH-3, S-61, and S-62). Under the agreement between the two companies, GE licensed Columbia to produce all procurable spare parts under a Federal Aviation Administration (FAA) Production Certificate, utilizing OEM drawings and specifications.

“We have finally realized that we had built the capability that was so honed and so proficient, in support of ourselves, that it would serve as a good support system within the general market,” said Bandy.

“As a matter of fact, with Bristow, that was kind of our concept: that we would deploy our capabilities to the benefit of their organization,” he added. “Now we will just look for the opportunities to replicate that process more broadly in the engine MRO/manufacturing segments.”

Another avenue for growth is in the 234 itself, which is due to further evolve in the hands of Columbia’s engineers. “Part of the plan is to advance the 234’s performance capabilities and the technology incorporated into the aircraft,” said Bandy, adding that the company is considering rebranding the next generation of the type as the 234-II. “We have never really taken credit for the fact that that aircraft has evolved fairly significantly over the time that we have operated it,” he said.

All told, it’s fair to say the team at Columbia is positive about the opportunities presented by a changing industry. Under new ownership and driven by its famously tandem-rotor fleet, Columbia is ready for significant growth.

“This company has always risen to challenges, and we are very excited about what is in front of us with this new ownership and their plan,” said Bandy.

This is a great article

I got my helicopter commercial in 1965, and have extensive maintenance background with an A&P license and IA.

Good luck with your wonderful system..