Now entering its 10th year of operation, maintenance, repair and overhaul (MRO) provider Aeromni Aerospace offers an unusually broad range of services. Located near the Langley Regional Airport in British Columbia, the facility is a one-stop-shop that handles almost every MRO need for fixed- and rotary-wing operators.

The company works on airframes, instruments, avionics and accessories across a spectrum of manufacturers including Bell, Sikorsky and Airbus Helicopters, and also offers parts/helicopter sales across the globe.

“We can basically take an aircraft and refinish the whole thing from top to bottom. . . . We can overhaul and repair almost everything,” said Rikkert Vos, Aeromni Aerospace’s vice president, adding that the only thing the company has not yet tapped into is the business of engine and dynamic component overhauls. “I believe in Canada we’re the only [MRO facility] that has this range of scope.”

The company was founded by Wei Lin (who today serves as Aeromni’s president), having 23 years in the aviation industry and a degree in electronics engineering.

Aeromni didn’t expand into the maintenance side of the business until Vos, with 21 years in aviation, joined the company in 2013. Together, Lin and Vos opened a facility in Langley, and Aeromni Aerospace grew.

Starting out as a one-man operation in 2008, the company now has over 10 employees who allow the business to smoothly cover its broad workload.

While it has a wide Canadian customer base, the company has expanded into the overseas market and recently opened a location in Australia serving Asia-Pacific.

Covering the bases

Aeromni has the ability to overhaul and perform instrument and avionics maintenance on almost any helicopter, but Vos said the recent demand has been primarily on Airbus products — particularly the AS350, AS355, H130, and H120.

“Brian Carandang [Aeromni’s chief engineer] and I have been working on the AStar for 16 years,” said Vos. “We both have extensive knowledge of the aircraft.”

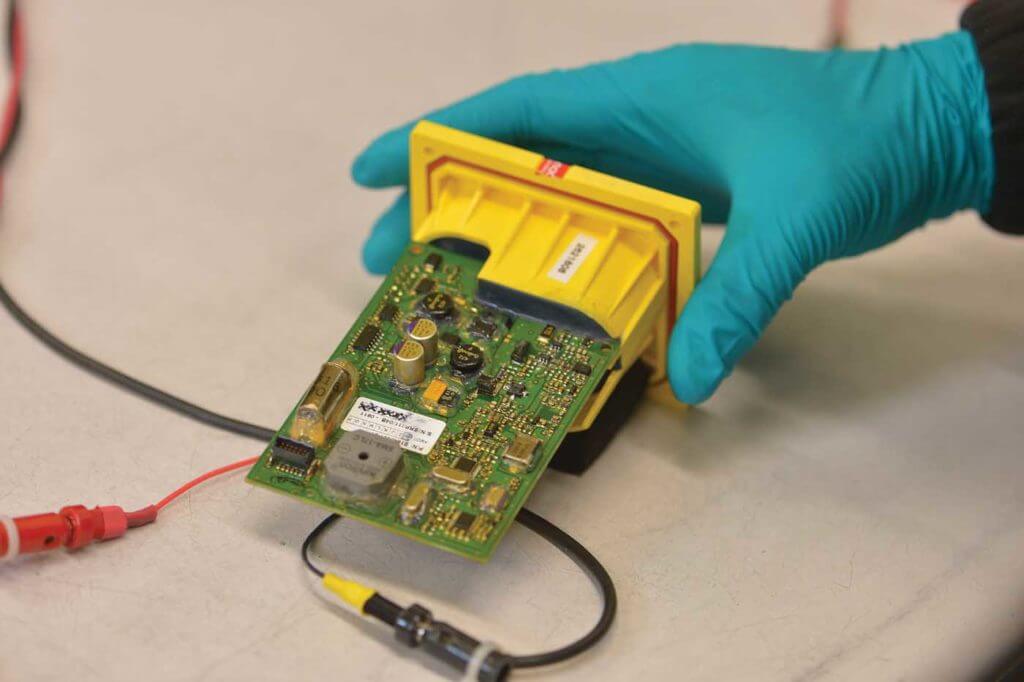

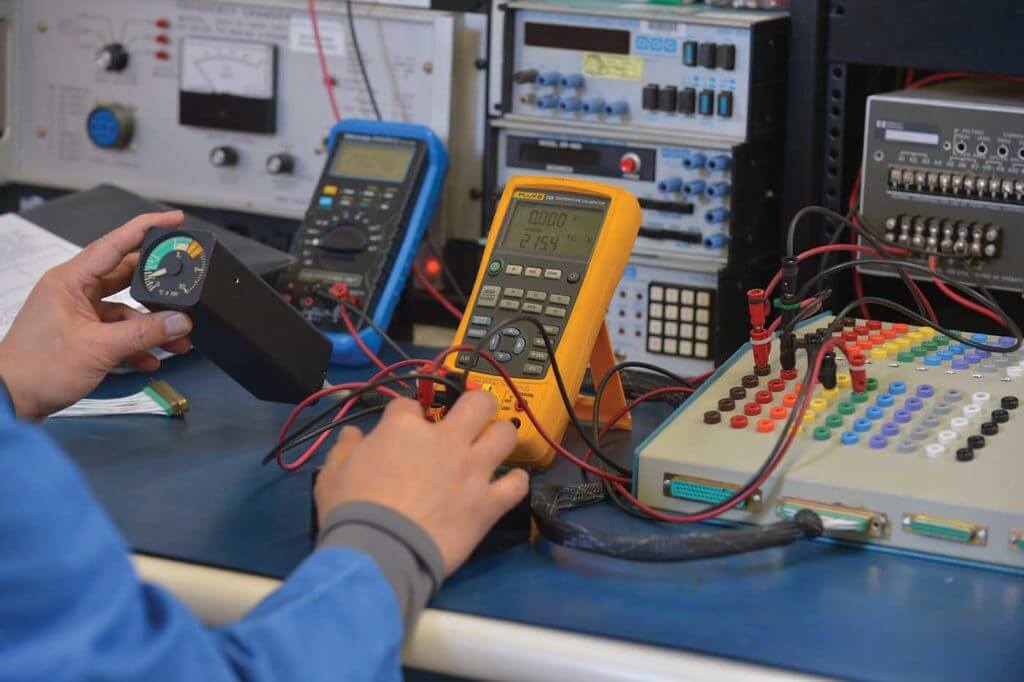

And when it comes to avionics, installations and upgrades are common jobs for Aeromni’s licensed avionics specialists. Andy Pang, Aeromni’s installation manager, and his team perform anything from radio upgrades to full aircraft re-wires, offering helicopter operators a fresh start with their aircraft. The company has performed complete aircraft re-wires on two Bell 206 LongRangers within the last year.

The level of expertise of the company’s avionics technicians mean it is able to build an operator’s “dream” dashboard for a helicopter. Aeromni uses supplemental type certificates (STCs) to create customized installations that allow different equipment to be installed on any airframe. The company takes the necessary steps to deliver the breathtaking cockpit that helicopter operators envision.

“We engineered a new instrument panel with precise fit and alignment of all the flight instruments,” explained Vos. “The new instrument panel was also powder-coated and laser-engraved for maximum durability and clarity.”

To elevate the level of customer service, Aeromni also has technicians who will work offsite at an operator’s facility when requested. “The avionics technician will fly to Whitehorse [Yukon] for example, and install a Geneva Panel or display. . . . We work offsite quite often,” he said. “We’re lucky to have a good team supporting us in maintenance and bench repair.”

The company also offers 12-year aircraft inspections, performing seven on Airbus AS350s and EC130s in the last three years alone.

Out of the many services Aeromni offers, its largest market is selling and exchanging aircraft parts — and this is a sector that the company has migrated into within the last few years.

Vos said the company will purchase aircraft to part out — taking various helicopter parts from aircraft and repairing/overhauling them to sell or exchange to operators. But Aeromni doesn’t solely offer overhauled parts for sale; it provides new surplus parts to its customers, as well.

Keeping a large inventory, Aeromni also stores spare parts to be able to provide them to customers if they need them at short notice. “Our inventory is quite large,” said Vos. “Our capabilities list is… pages and pages long.”

Making flight affordable

Because of its ability to perform such a wide variety of services in-house, Aeromni is able to keep repair costs low — an advantage any operator would appreciate.

“We’re not farming anything out except for paint, major dynamic component overhauls and engine work; the rest of it is all done here,” said Vos.

One of Aeromni’s major recent projects involved converting an Airbus AS350 B into a B2 and replacing the aircraft’s conventional push-button switch console with the reliable and modern Geneva switch console. Partnering with Vector Aerospace for aircraft paint and Turbomeca (now Safran Helicopter Engines) Canada for the addition of an Arriel 1D1 engine, the entire helicopter was dismantled, painted and cost-efficiently converted into a B2 in just four months. The transformed AS350 B2 is once again being used for mining purposes in Northern British Columbia.

Indeed, the majority of Aeromni’s business comes from within Canada — much of which is local to the British Columbia-based company. While it mainly focuses on the helicopter industry, a small percentage of its business comes from the fixed-wing industry.

Aeromni provides instruments and avionics to independent airlines in British Columbia like Richmond-based Harbour Air Seaplanes. But Vos said the company typically only provides maintenance on helicopters.

One of Aeromni’s most frequent customers for helicopter maintenance is the Canadian Traffic Network (CTN) in British Columbia (a division of the Global Traffic Network). CTN flies Robinson R44 Raven IIs for traffic and newsgathering purposes. In order for news operations to run smoothly, the aircraft must be regularly maintained — and Aeromni is the MRO for the job. “They’re coming in here probably once a week and we do maintenance for them,” said Vos.

Currently, Aeromni’s maintenance and repair technicians see roughly 12 aircraft go through the shop in a year, Vos said. And with optimism for growth, the company is aiming to expand to other overseas locations beyond its current range.

After 10 years of success, the sky is the limit for this cost-efficient and multi-disciplined MRO facility. “Every employee is a sales person for our business, and it’s important they are happy and engaged,” Vos concluded. “A satisfied employee results in a satisfied customer. And because of our culture, I’m confident we are only going to grow from here.”