Billings Flying Service (BFS) has never been afraid of trying something new when it comes to aircraft types. The Billings, Montana-based utility operator also has a history of success when taking former military machines and putting them to work in the commercial sector. So in early 2014, when two U.S. Army Boeing CH-47D Chinooks appeared for auction on a U.S. government General Services Administration (GSA) website, Al and Gary Blain — the founders and owners of BFS — were quick to pounce on the opportunity they saw in front of them.

The pair purchased the aircraft, which were the first two former military CH-47Ds to be auctioned to civilians, and began transforming them for their new life as heavy-lifters in the commercial world.

Today, the BFS fleet has eight Chinooks, and they are joined by one Sikorsky UH-60, five Bell 206s, five Airbus AS350 B3s, one MD 500, and one Hiller 12B. The range of operations is fairly typical of a utility operator, spanning aerial construction, firefighting, and support of oil-and-gas and mineral exploration work. But the relatively unique fleet also allows for more niche operations, such as government contracting, disaster relief, and movie work. And while it’s very much a family company, BFS has a substantial staff of about 85 employees, including 20 pilots. All the pilots are qualified on the Chinook and some are dual qualified on the Black Hawk.

Al and Gary describe BFS as a second-generation company, having inherited their passion for aviation from their father. Gerhart Blain founded Blain’s Spray Service — a fixed-wing crop-dusting business — in the early 1950s, and he joined the rotary-wing community a couple of decades later, when he learned to fly a helicopter in the 1970s.

Gerhart’s sons were actively involved in the family business from a young age, both as ground support and as pilots. The pair ultimately left to pursue careers as commercial airline pilots with Continental Airlines, but still flew for the family ranch in their time off. Continental went through bankruptcy in the early 1990s, and though the Blain brothers didn’t lose their jobs, the instability of the career led them to look for other opportunities.

In 1995, they bought a surplus Bell UH1-E Huey and set it up for spraying. By 1997, they had their first call-when-needed (CWN) contract with the U.S. Forest Service (USFS). That first Huey was the start of a number of helicopters the company purchased and refurbished, put to work, or sold, with the business really taking off with a busy wildfire season in 1998. Gary and Al flew over 1,000 helicopter hours that year — spraying weeds and managing the buying, selling, and overhauling of Hueys, all while still flying for Continental Airlines. “We were the good type of busy!” Al told Vertical.

A heavy move

Horse traders at heart, Al and Gary saw the possibilities in an Aérospatiale SA330 Puma they discovered for sale in Japan in 2001. After shipping it to the U.S., they began the certification process, and shortly after that, learned to fly it. With the Puma, BFS was able to expand into the Type 1 (heavy helicopter) firefighting market, bidding on contracts that would have never been possible with the Huey. The Puma won its first firefighting contract with the USFS in 2002, and due to BFS’s success with the aircraft, Al and Gary decided to purchase another two Japanese Pumas.

BFS operated its Puma fleet for a few years, eventually selling the aircraft to a company for use on a Navy VERTREP (vertical replenishment) contract. The Pumas were replaced in the Billings fleet with two Sikorsky S-61 As. “[It was] like I bought a spaceship — they were built like a truck, lifted like crazy, and were super reliable,” recalled Al. “I am not nostalgic about helicopters, but I loved the S-61. We operated them for many years on construction jobs, firefighting, and training.”

In July of 2013, tragedy struck the family. Al’s oldest son, AJ, was killed in an accident while doing seismic work in a UH-1 Huey in Colorado. The loss was so devastating, Al and Gary considered leaving the aviation business behind. But with aviation being a major part of their DNA, they ultimately decided to continue.

It was shortly after this that the CH-47Ds appeared for auction. “We were bidding against larger and more well-funded companies, but we were determined to move on these machines,” said Al. BFS ended up getting both airframes, and began building its Chinook program. Requiring spare parts, hangar space, pilots, and maintenance infrastructure, the effort took every nickel the company could scrape together.

BFS also set to work writing a type certificate for the aircraft, working closely with the Federal Aviation Administration’s (FAA’s) aircraft certification to ensure its success. BFS believes the certificate was a world-first for the CH-47D.

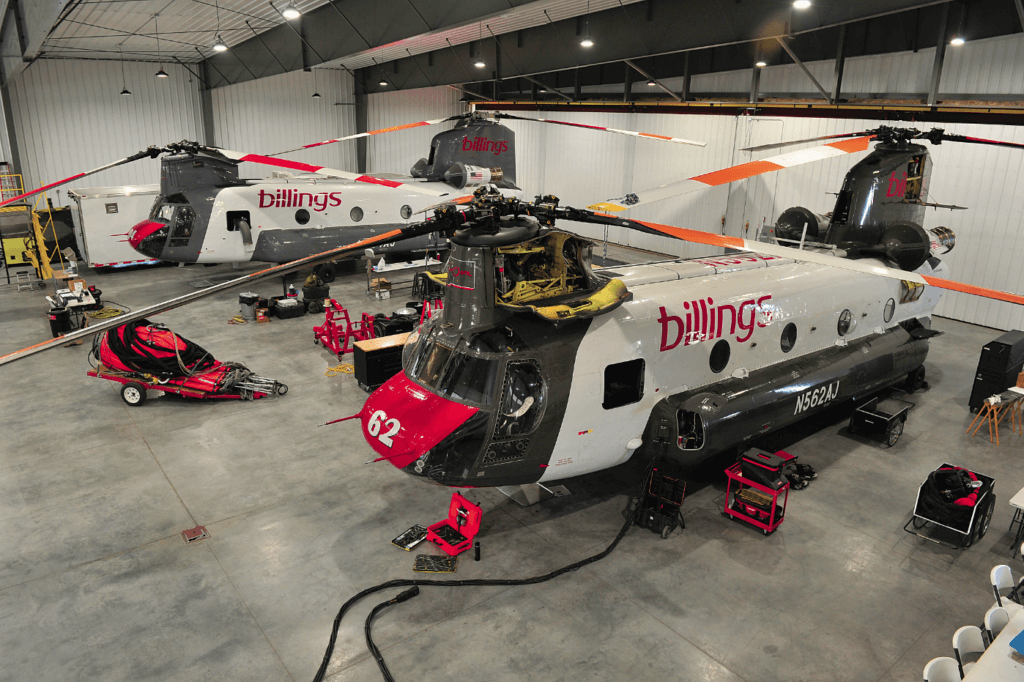

The Chinooks were initially operated out of the BFS hangars on its private airstrip outside Billings, but the company quickly realized that it was outgrowing these facilities. After a search for a suitable location that would allow it to comfortably expand, it found the perfect spot adjacent to the Billings International Airport.

In 2015, BFS broke ground on a 25,000-square-foot hangar and maintenance facility, designed to house six Chinooks with blades on, eight Chinooks without blades. The company is also building a new office facility, which is due to be finshed in September 2018.

Of the eight Chinook airframes in the BFS fleet, six are flying, and it began operating the type on CWN contracts with the USFS in 2015.

For operators and customers, the Chinook certainly presents impressive numbers, with 140+ knots cross-country, a maximum range of about 350 nautical miles (650 kilometers), up to 25,000 pounds (11,340 kilograms) on the cargo hook, and exceptional “hot and high” performance. As the aircraft is still in production, spare parts are readily available, but to ensure BFS has sustainability for decades to come, the company is adding MRO capabilities for the CH-47D.

Building the Chinook’s tank

Up until this summer, BFS operated the Chinooks solely with 2,600-US gallon (9,840-liter) variable drop buckets for firefighting work. The idea to develop an internal tank for the Chinook had its roots in a contract BFS had with Kawak Aviation to design a bottom-filling refill pump for the buckets. Kawak was able to produce a retrofit kit that consisted of a single 1,600-gallons-per-minute (6,050-liters-per-minute) pump. The new system reduced overall bucket weight by 425 pounds (190 kilograms), and proved to be reliable and maintenance-free for an entire fire season.

Given the success of the bucket retrofit program, Kawak and BFS formed a partnership in 2016 to develop a new internal firefighting tank for the CH-47D. In May 2018, after many months of design, development, and manufacturing, Kawak received a supplemental type certificate (STC) from the FAA for the new “aerial liquid delivery system” and the auxiliary hydraulic system that powers it.

The system consists of a 2,500-US gallon (9,465-liter) internal water tank, a 128-US gallon (485-liter) foam tank, a fully independent 50-horsepower hydraulic system, a 4,000-US gallons-per-minute (15,140-liters-per-minute) refill pump, a unique sliding belly door water drop design, and cockpit controls for the system. The tank can release 90 percent of a full 2,500-US gallon load of water in just three seconds.

Kawak subcontracted Trotter Controls of Fort Worth, Texas, to develop the door controls for the tank, and, in opting for a sliding door instead of a clamshell-style door system, Kawak was able to create a more effective drop pattern while still utilizing the existing hook well. The aircraft’s hydraulic system produces more than enough power for the firefighting system, which does not interfere with the aircraft functions necessary for flight. BFS said this type of tank system provides high performance, safety, and ease of maintenance.

One key aspect of the system is a live telemetry functionality, which automatically records how much water is taken on, how much is dropped, and where it was dropped. This information is then transmitted to the agency managing the fire for analysis.

“We are proud of this tank design,” Kawak’s Andrew Sawyer told Vertical. “The pumps are powerful and able to fill the tank in under 30 seconds, giving the aircraft more time on target during its flight cycle.”

He said the tank was proving itself so far, but that Kawak would continue to watch its performance and offer support when necessary. “We will refine the system and incorporate what we find into the next evolution of the tank system for the next BFS Chinook to come online,” said Sawyer.

Al Blain said BFS was happy with the system’s development to date. “We will watch its durability and hope to do some weight reduction and refinements in the future,” he said. “We will keep the Bambi Buckets along with the Kawak pumps; we are very happy with their performance and they still have a place in aerial firefighting.”

Putting the tank into service

BFS pilot Mike Strasser told Vertical that all the company’s pilots enjoy flying with the bucket on the end of a long line — which allows for great precision for load placement — but that there were increasingly restrictive requirements affecting where buckets could be flown, particularly around urban interfaces. Because of this, he said the tank will prove particularly popular in more densely-populated areas such as Northern California.

Strasser said the plan with the Kawak-designed tank was to increase the advantages of using an internal tank over existing products. “I have seen in these first weeks of the fire season the Kawak pump is capable of filling [the tank] at 100 gallons per second,” he said. “This reduces the time spent snorkeling at the water source during a very critical time of the flight.

“My main worry was the drop pattern of the water, which proved to be unfounded. With water having to come out from the cargo hook well of the Chinook, which seemed small compared to a S-64 Skycrane tank door, I was afraid the water would not come out fast enough. Within one day of flying the [Chinook with the] new Kawak tank, it showed that water comes out as a solid beam that I can steer around the fire’s edge.”

The Kawak tank system also gives BFS pilots the option to split the water drop and use different coverage levels for each drop.

“This is our first season with the internal tank, and I only expect the system to get better,” said Strasser.

Brian Jensen, another BFS pilot, spoke to Vertical about the differences operating with a bucket and the internal tank. “The long line bucket is more popular in the Northwest and areas with heavy timber,” he said. “It can reach into smaller dip sites, like ponds or rivers that are surrounded by trees. In these areas, a bucketed aircraft can generally find a dip site closer to the fire, because it does not need as much room as a tanked aircraft.

“It also has the benefit that it can make drops at a lower airspeed than the tanked CH-47D, which helps the water penetrate the dense timber canopy and get to the source of the fire.

“The new pump and actuator in the bucket are awesome,” Jensen continued. “They’re much more reliable, and reduce the time spent at the water source. The pump itself is extremely fast and being as it’s a single pump, we save a lot of weight.”

Jeff Cook, BFS’s director of operations, told Vertical that the tank and bucket each have their own place. “The modified bucket is working great, and the tank, although new, has a great design that we have been impressed with,” he said. However, he added that the operator plans to increase the number of its Chinooks that are flying with the tank.

Along with the Chinooks, BFS has bolstered its fleet with another military stalwart — the UH-60A Black Hawk. Over the past couple of years, the operator has acquired three, selling two to other operators. “The Huey, which we dealt with for years, is still a great machine and has many years of life in it, but we see the Black Hawk as a part of the future in the utility and firefighting market,” said Gary.

“The Sikorsky S-61 is aging and parts are becoming hard to come by, so its logical replacement is the UH-60 series.”

Al’s son Bridger, who has an engineering degree from Montana Tech, wrote BFS’s UH-60 type certificate. He is part of the next generation of Blains to be actively involved in BFS. Bridger works in sales and acquisition of aircraft, and is certified to fly the CH-47D, UH-60, and Cessna CJ series, among others.

BFS is now in the process of “finishing up” its UH-60A and plans to use it in the utility and firefighting market. “Although the UH-60 is a bit more expensive to operate than a Huey, it simply does twice the work on its worst day and better than that on its best day,” said Gary.

BFS plans to keep an eye on the military surplus UH-60 market, anticipating the release of the more capable L models, which will provide even more lift and performance at high altitude.

In addition to its rotary fleet, BFS operates three fixed-wing aircraft to support its firefighting operations, mostly around the Western U.S.

“We want our firefighting aircraft operating with as little, if any, downtime as possible, so we have a Cessna Citation, Cessna Caravan, and a Pilatus PC-12 to move replacement parts into airports where the Chinooks are operating from,” said Gary. “Both the Caravan and the Pilatus can carry a Chinook engine and any transmission used by the CH-47.”

The Chinooks carry a pickup truck inside their cabin when flying out to fires, and this can meet the fixed-wing supply aircraft to collect parts, said Gary. The aircraft are also used to move flight crews and mechanics to jobsites.

The Blains proudly describe their life’s work as safely providing a quality service. With the Chinooks and their newly-developed firefighting tank now part of the BFS offering, it has taken the breadth of that service to another level. The secret behind the operator’s success, Al said, is its employees.

“It is one of our missions to create an environment where people can raise their families and work for a lifetime,” he said. “We have very high expectations of them and they have very high expectations of us.”

For them, and in the memory of his son, AJ, Al said the company continues to strive for excellence each and every day.

“We wake up in the morning thinking about helicopters and how to do [our work] better, and we go to sleep at night thinking about helicopters and how to do [our work] better,” he said. “I want AJ to be proud of what we are doing and how we are doing it.”

Awesome

Go “Billings Flying Service Trail Blazers”. So proud of all the good work you do. May the Wind Always Be At Your Back.

It’s great to see these hard working choppers still at it. I pulled maintinance and crew duty on these 47+ years ago. I brought one out of cannabilization piece by piece.

Good fortune ahead for you all and may the wind be at your back.

Tom